Electrical Energy Production [EU2]

This efficiency has been illustrated by a concept called “dance with the waters”, which establishes a system of coordination of decisions regarding the scheduled availability of generation and transmission assets, systematically to the hydrological signal and eventually to the consumer demand signal.

Dance with the Waters

[103-2, 103-3, 201-2, EU6]This concept covers integrated works of the Superintendence of Engineering, Construction, Maintenance and Operation.

The production of energy in a hydroelectric powerplant is directly related to four factors: turnaround, machines availability, availability of transmission and consumption. As important as these factors, it is the coordination in its use, focusing on optimizing the production and the flow of energy.

The water from the Itaipu reservoir depends on rainfall and reservoirs in the Southeast and Midwest regions, as well as the flows of the incremental rivers such as Piquiri, Ivaí and Tibagi in the state of Paraná.

The engineering, construction, assembly, operation and maintenance activities directly affect the availability and forced unavailability of plant equipment, including the generating units. Preventive maintenance and operation inspections are two examples of these activities. In 2018, there was no human failure in real-time operation with impact on production and/or equipment, which contributes to the prevention of accidents and to a very low rate of forced unavailability of 0.09%.

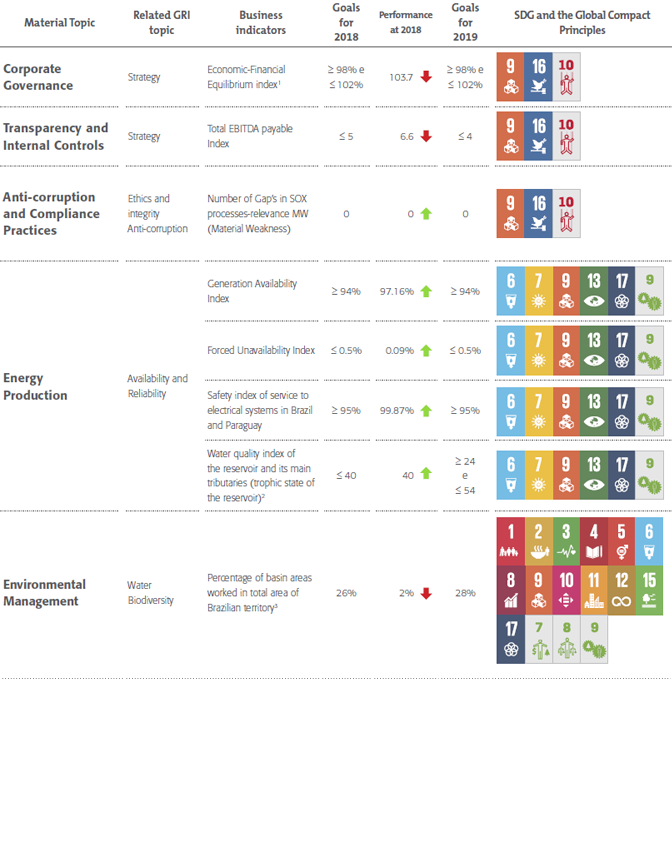

The schedule and the execution time of maintenance interfere with the programmed availability and the forced unavailability of the generating units, which even exceeded their goals in the year (read the table of goals available on pages 16-17). The results represented a high reliability index of the system, since they were almost all the time ready for production and the water from the reservoir was availed virtually without waste.

This annual plan of rigorous maintenance is safely combined with the hydrological scenario in order to meet the consumption demands of countries, which happen through the National System Operator (ONS) in Brazil, and the state-owned Ande, in Paraguay. They also stand out as part of the Dance with the Waters, the analysis of risks and opportunities associated with climate change and subsequent adoption of measures. The constant control of the water level in the reservoir, either in a period of scarcity or abundance, and the pursuit for the optimization of production generates effects in the sector of the two countries. [201-2]

Availability Factor of Plant Generating Units

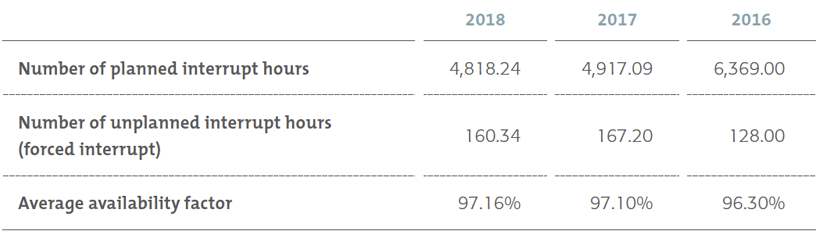

[EU30]In 2018, the best historical index was recorded, of 97.16%, fulfilling the established goal of obtaining a value equal to or greater than 94%. The average availability factor measures the percentage of time during which the generating units remained in operation or were available for energy production.

Operative Capacity Factor

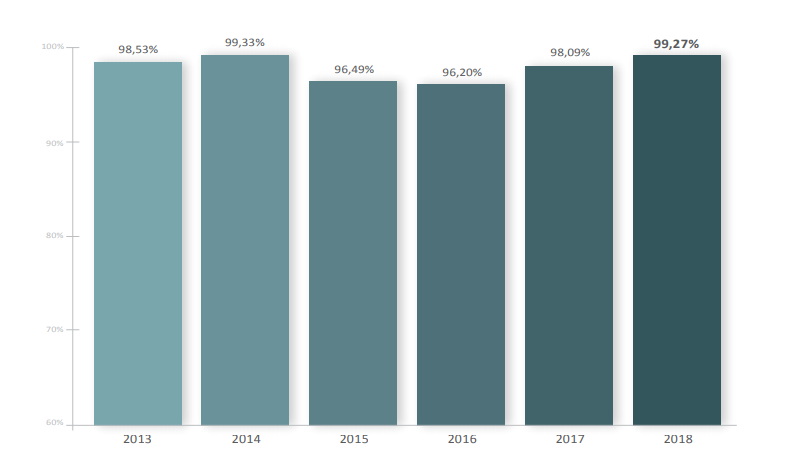

Operative capacity Factor (FCO) of 2018 was 99.27%, above the average value of the previous five years (97.73%) and the second highest in history, that is, almost every volume of water that passed through the plant was transformed into energy, as the graph below indicates.

Dam and Flood Safety in Paraná River

[103-2, 103-3, 413-2, EU21]

Every four years, as a security measure, Itaipu conducts a Civil Consultants Meeting - Board. Created in 1974, it is a group of Civil Engineers recognized for its high level of technical knowledge about the construction project of the plant and the performance of its civil structures.

These specialists analyze the data on the conditions of the dam structure (auscultation) gathered over the past four years and perform visual inspections throughout the plant to assess their conditions of use and safety. As foreseen, the Board 2018 was carried out, confirming that Itaipu remains among the safest dams in the world, and presenting preventive actions to be undertaken in the coming years to be evaluated on the Board 2022.

Constantly, the safety conditions of the dam are monitored by about 3,000 equipment, as well as by the technicians of Itaipu itself, who perform visual inspections and manual readings to check if there is any alteration in the structures, foundations and Instruments. Also, with a focus on security, the company maintains the Center for Advanced Studies on Dam Safety (CEASB).

Because it is a conventional hydroelectric powerplant, that is, without the possibility of a sensitive variation of the quota of its reservoir, Itaipu has reduced capacity to dampen floods. Despite this, the plant seeks to operate in order to minimize flood impacts in communities below the dam.

To ensure the safety of the population, an emergency action plan with a binational reach is maintained, and a Flood Commission monitors the volume of water received, including rainfall located on the reservoir and its contribution basin. The company issues a daily hydrological bulletin, informing levels of the Paraná River downstream of the plant at various points of interest, on the Brazilian and Paraguayan banks, as well as the States considered as normal, attention, alert and severe. [413-2, EU21]

Whenever the hydrological Yesulations identify possibilities of social impacts resulting from increases in levels in the Paraná River, the Commission informs the population, through civil defense and other public agencies in Brazil and Paraguay.

Operational Safety Management System

Application capable of simultaneously monitoring more than 15,000 variables of various systems of the company and update them every ten minutes. The Operational Safety Management System (SOP) analyzes and classifies data and information such as availability, unavailability, availability with restrictions, programmed or forced impediments of all relevant equipment and its substations in such a way as to measure how much the operation at each moment is compliant with the ideal conditions of the project.

SOP has the format in circular chart, with four safety strips: “great”, “good”, “alert” and “critical”. The tool is available, in real time, including for managers and senior management of the company.

Technological Update of the Generating Units

[102-15, 201-2]The first stage has an expected duration of four years and covers the elaboration of the executive projects, manufacturing, testing in factories, updating the systems of the control rooms and local tests.

One of the main challenges for the company, the technological update of the 20 generating units is expected to last 14 years and the investment will be US $660 million. The first phase of the bidding (pre-qualification of companies and consortia interested in participating in the work) was completed in December 2018.

In the beginning of the 2000’s, the equipment gained a “layer” more modern, with the Digital System of Supervision and Control (SCADA) and the Energy Management System (EMS), initiating the process of digitizing the plant. The units U9A and U18A, deployed between 2004 and 2006, also use digital control technology.

In this process of technological updating, the intention is to fully replace analog equipment and systems with digital equivalents, with new information and functionalities. For this, a multidisciplinary team composed of Brazilians and Paraguayans from the plant itself has been coordinating several studies over the last few years.

More than replacing, the plan is to rethink features and processes, in addition to allowing a more detailed reading of the generating units, which are in excellent condition and will not be part of the scope of the update at this time. The focus is on the control, protection, supervision, regulation, excitation and monitoring systems of the generating units and substations, such as circuit boards, sensors and gauges, among others, scattered over several kilometers along the power house, dam, substations and spillage.

The first stage has an expected duration of four years and covers the elaboration of the executive projects, manufacturing, testing in factories, updating the systems of the control rooms and local tests, to only then advance to the next phase, of stopping the generating units. The expectation is that the systems of two machines will be upgraded annually.

The upgrading of the Itaipu powerplant is a complex activity and can also be considered as one of the most challenging for the electric sector, which has required a strategic accompaniment of directors and advisors. The ultimate goal is to ensure that the plant’s equipment maintains its reliability and is ensured the continuity of the company’s high performance in the coming decades, with even better scores of energy production and reflections including in the economy of the two partner countries. The higher the production of hydroelectric plants such as Itaipu, for example, the lower the risk of Brazil and Paraguay needing to resort to the use of thermoelectric, whose energy is more expensive and pollutant.

Português

Português

Español

Español